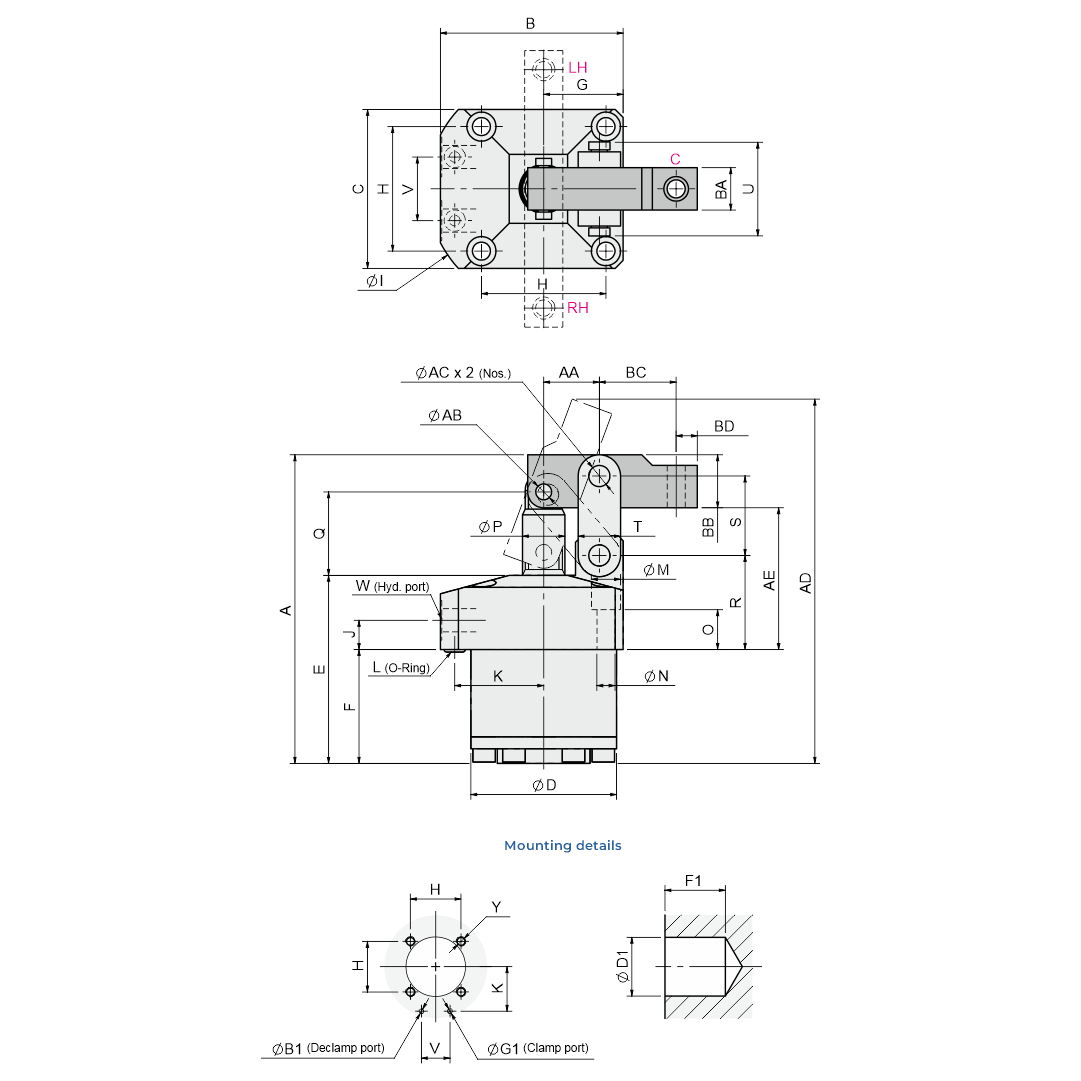

Link clamp

Information

The Link clamp is designed with sufficient unclamp angle and

compact size so that there is no interference when loading and unloading

the workpiece takes place, maximizing designer convenience.

- Hardened and chromed alloy steel piston rods run longer with less wear

- Wiper seals reduce contamination of dust for the long run of the Link clamp

- Special coating on the cylinder body helps prevent Rusting and scratching

Specifications

- Minimum operating pressure: 10 Bar

- Maximum operating pressure: 70 Bar

- Operating temperature: 10 - 70 °C