Swing clamp

Dynamic Hydraulics is a reliable Manufacturer and Supplier of Swing Clamp Cylinders in India, offering high-quality hydraulic swing clamps designed for precision, durability, and consistent industrial performance.

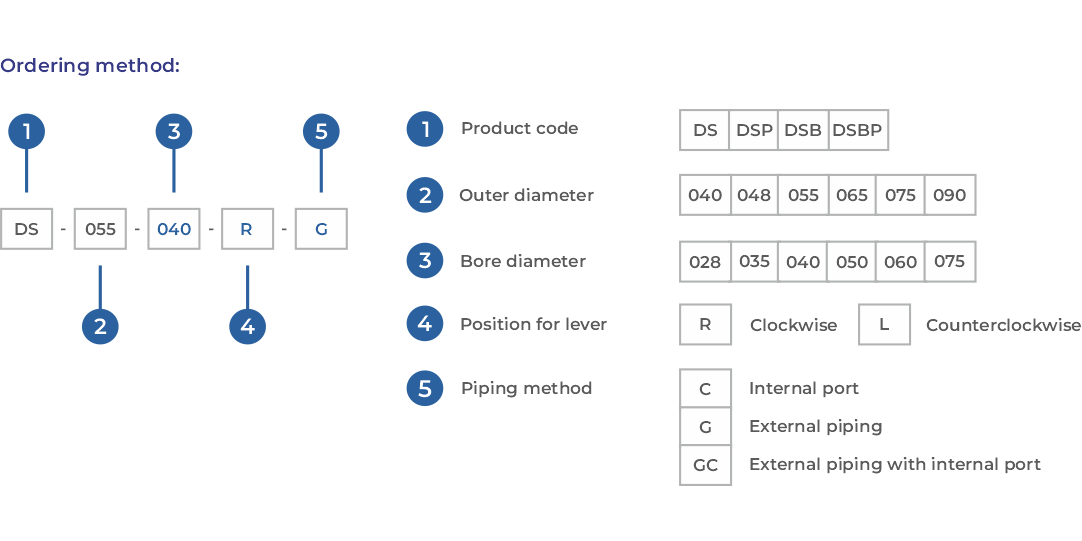

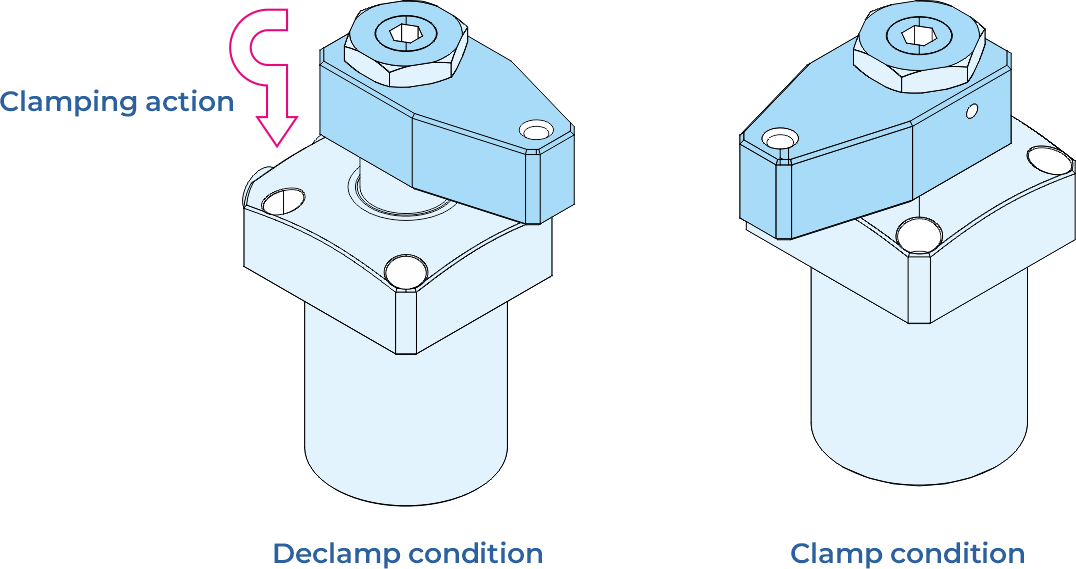

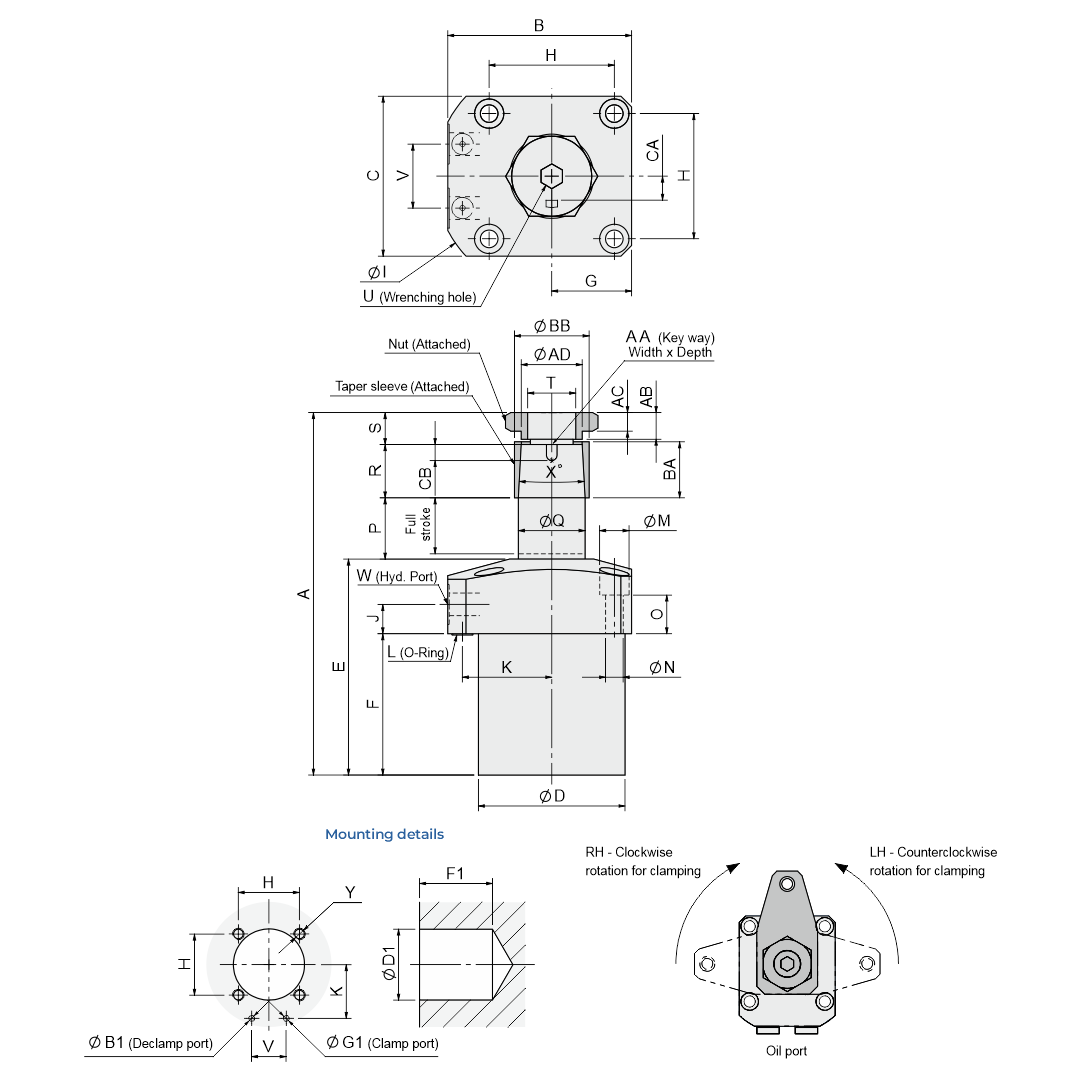

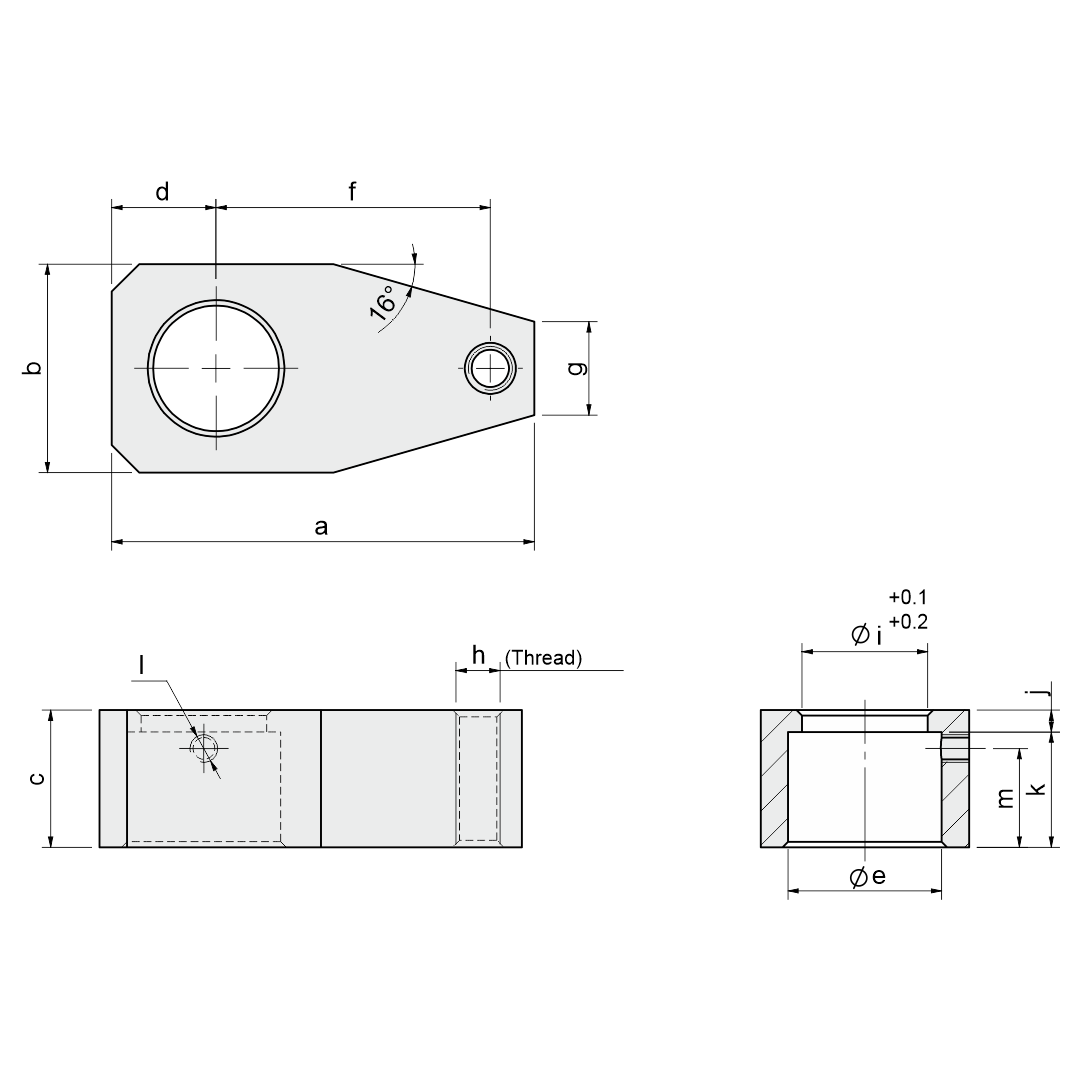

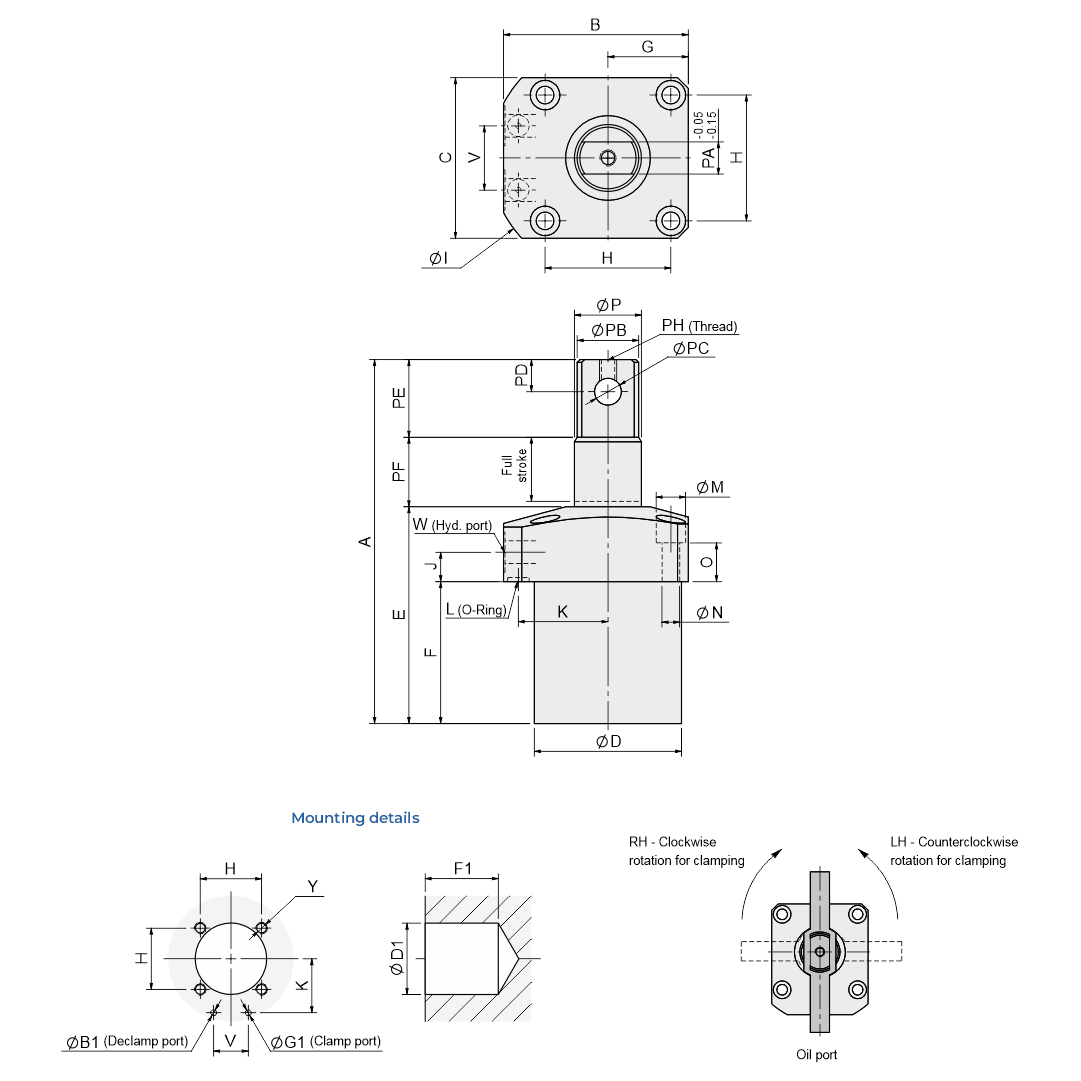

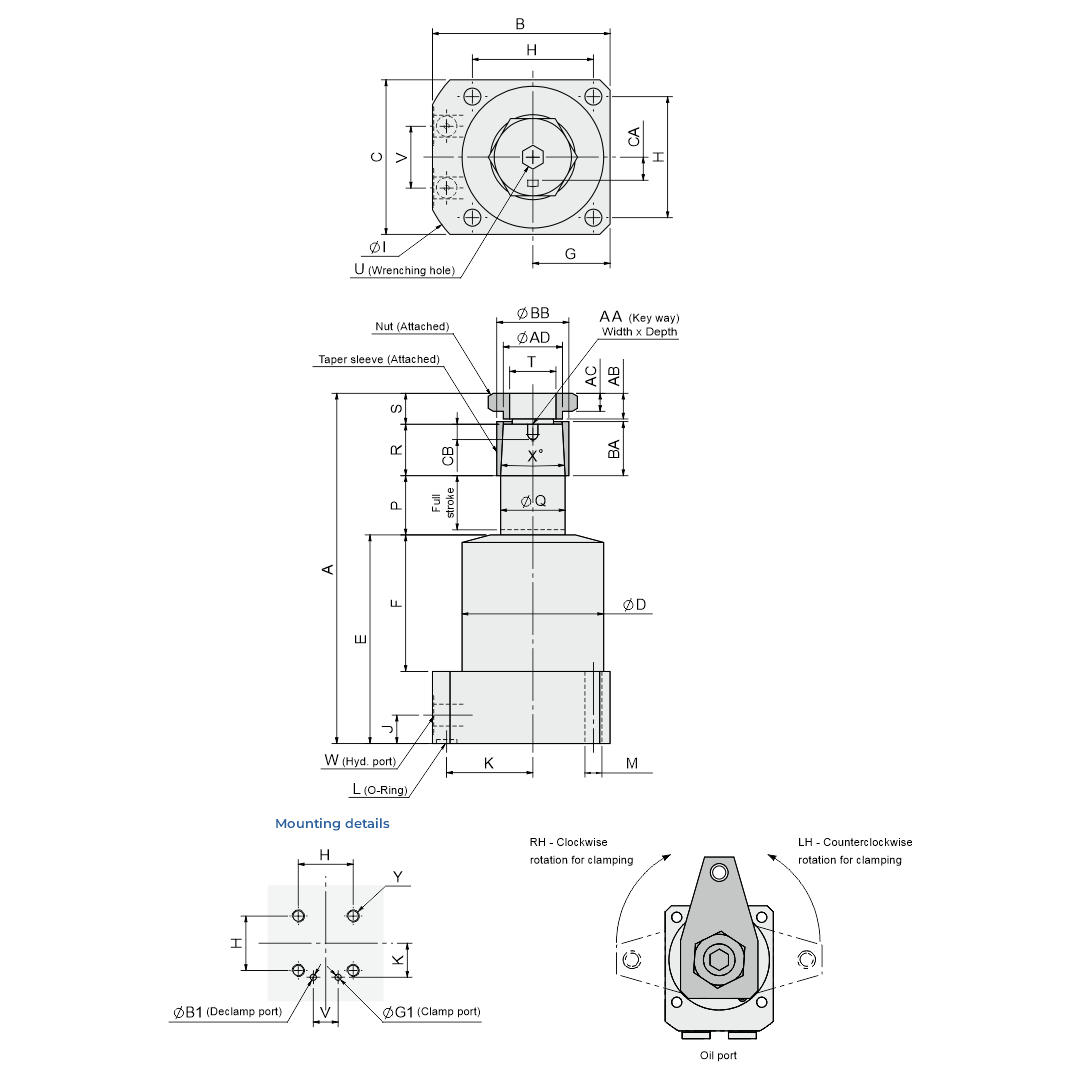

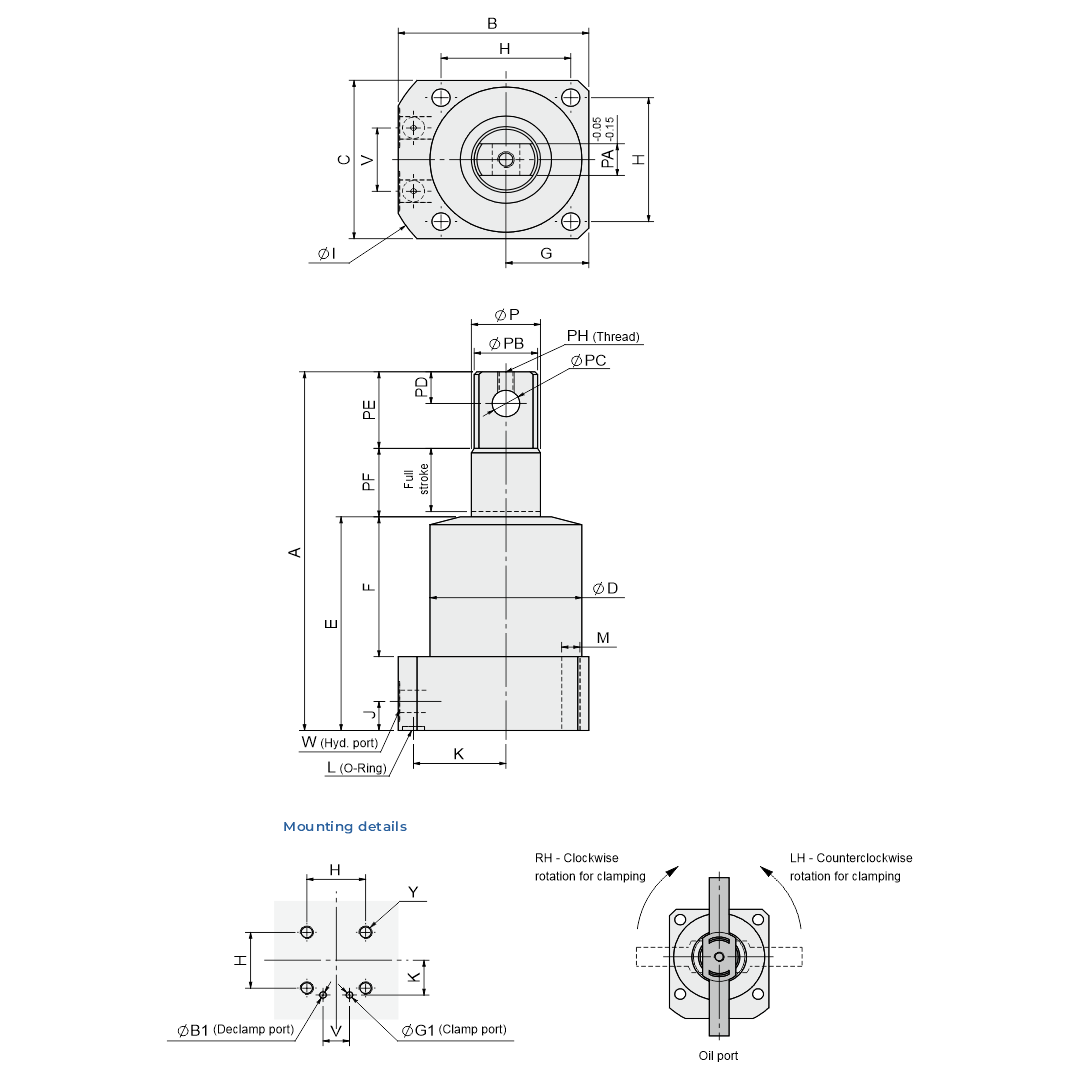

Our hydraulic swing clamp cylinders rotate 90° (clockwise or counter-clockwise) to position over the workpiece and then apply a strong vertical clamping force. This ensures secure holding, excellent stability, and high accuracy during machining and assembly operations.

Information

A Swing Clamp Cylinder is a hydraulic clamping device that rotates 90° (clockwise or counter-clockwise) over the workpiece and then applies a strong vertical clamping force. This ensures:

- Secure workpiece holding

- High machining accuracy

- Quick setup and operation

Swing clamp cylinders are essential in industries where fast, repeatable, and precise clamping is required.

Features of swing clamp cylinders

- Heavy-duty construction for long service life

- Hardened and chrome-plated piston rods to minimize wear

- High-quality wiper seals for dust protection and smooth operation

- Corrosion-protected body for improved durability

- Efficient performance at 15–70 bar operating pressure

- Suitable for working temperatures from 10°C to 70°C

Applications

- Our hydraulic swing clamp cylinders are widely used in:

- CNC machining and milling operations

- Drilling and automated production lines

- Assembly fixtures and jigs

- Precision manufacturing requiring fast and secure clamping